Laser cutters and engraving machines have seen a recent surge in popularity and availability. Never has there been such a wide range of options for the creators out there, with machines large and small, with wildly differing capabilities and use cases. So, how do you know where to start, what do you need and how much should you spend?

For most, a purchase will be made based on a final product. For example, if you want to make wooden construction kits you will need a machine capable of cutting wood and at sizes that suit those needs. This would likely be a very different machine than one chosen for engraving custom pins, dog tags or the like, which would probably mean a different kind of laser technology.

This is where something like the F1 Ultra comes in, as it crosses some of those boundaries, at least in part. It offers both Fibre and diode lasers in one machine, meaning it can cut and engrave (as well as emboss, more on that later). It doesn’t have the largest working area however it does have some handy accessories that can transform it into a production workhorse.

But does it serve its purpose as a commercial grade device, that can also be used by creatives for more individual projects? I’ve spent weeks using it, comparing it to my other laser cutters and the many that I have tested, putting it through its paces.

Set-up and build quality

Unlike many laser cutters, the XTool F1 Ultra is pretty much ready to go as soon as you take it out of the box. There is no construction needed at all. Simply remove the packaging, not forgetting the interior, which houses some components, plug it in, along with the extraction tube and controller plus the USB lock key and it is ready.

There are a couple of first steps like initial calibration but this takes seconds. Just remember to remove the lens cover, or you’ll be scratching your head. Other than that and connecting the power and USB-C cables, plus the exhaust tube, there’s really nothing to it. Boot up the Tool software and you are ready to go.

Build quality is second to none. The F1 Ultra is incredibly well built, and made from solid materials that will last for years. Even the handle on the green plastic cover is made from metal and the ports for connecting peripherals feel good quality.

If you go for the bundle with either/both rotary or conveyor options, you’ll find similar build quality and materials there too.

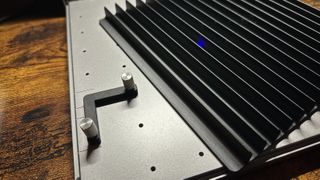

Unlike some lasers, the footprint of the F1 Ultra is fairly small, as the working area is 22cm x 22cm. The platform has some handy features, from an additional plate that has cooling fins built in, to an ‘L’ shaped screw-down guide, with a matrix of threaded holes across the surface to aid in placing your materials.

The build feels thorough too. The motors that lift and lower the top section for focus are smooth and accurate, the fan sucks air well, at least using the Excellent XTool SafetyPro purifier and the emergency stop is responsive.

The F1 can be connected wirelessly or via USB-C. I opted for a wired connection, due to the location on my desk but I tested the wireless connection and it worked flawlessly.

I’m also a big fan of the control panel. This could easily have been part of the machine but XTool has made a wise choice in keeping it a separate module, which has a decent cable, allowing it to be placed anywhere. This has a simple touchscreen interface, with physical buttons for focus adjustment, framing and starting a job, once it has been sent to the F1. I’ve seen people 3D print caddies for this so it can be attached to the lid of the F1, so get creative.

For me, I like keeping it close to the computer, with the laser further away. No matter how you like to work, the F1 Ultra definitely caters to those preferences.

What can it do?

At the most basic level, the F1 Ultra can cut, engrave and emboss materials from wood and plastics to ceramics, metals and stone.

It does so with dual lasers. One is a 20-watt fibre laser and the other a 20-watt diode laser. These lasers are powerful enough to cut through .4mm metal sheets, which may not sound like much but means you can go to town on interesting projects like business cards that have more interest than a simple printed paper one. Or you can design foldable metal toys and unlimited personalised items.

As well as the engraving and cutting, the F1 Ultra can also emboss designs, giving real depth to projects. Check out the coin below, engraved into a brass coin. This is done by creating a depth map, which the XCS software can then turn into layered passes of the fibre laser, each one taking different parts of the material away. Think of this like an FDM 3D printer layering material up but in reverse. These jobs can take a while but luckily you can pause and resume at will.

Lining a material up with a design can be a struggle on some machines, where you might need to use a pin to locate a corner or a camera to see a live view of the bed. The F1 uses a camera, which is my preference and it’s set high up so it eliminates some of the weird skewing you sometimes see. It’s not quite perfect but it’s pretty close. The F1 also has a framing guide, where you press a button and the outline of your design is projected down, making it very easy to place the material exactly where it’s needed. The combination of that and the camera means misaligned cuts are a thing of the past.

The way the F1 Ultra works is via stationary lasers, where the beam is directed via mirrors and a lens. Unlike larger machines, where the laser module moves parallel to the work surface. For engraved designs, this isn’t an issue. However, if you do want to cut thicker materials, the further towards the edges you get the more you will see a problem and that is angled cuts. While small the angles are noticeable so keep that in mind. It’s really only an issue for anything over a few millimetres but for people cutting larger, thicker materials, this machine probably isn’t on your shortlist anyway.

For the vast majority, the F1 Ultra performs admirably. It is accurate, pretty quiet and very fast. It can work at up to 10,000mm/per second. That sounds a lot but watching a business card design being engraved on a metal card it’s even more impressive. One of those blink-and-you’ll-miss-it moments.

Another very useful feature of the F1 Ultra is that it can work on curved surfaces, thanks to the motorised height adjustment. If it wasn’t for this, like a traditional XY gantry-style machine the laser would lose focus at certain points of the material.

The F1 Ultra can be bought with some accessories that take things to a whole new level. Rotary add-ons aren’t new and the F1’s is no different. It allows you to attach syndical items, like glasses and bottles, so you can engrave designs on them without any warping. The XTool rotary is made with the same attention to detail and quality of materials as the F1 and I would highly recommend it.

They also offer a conveyor add-on for batch processing. This is a pretty smart device and uses the camera to locate multiple items to engrave the same design on. It even adjusts the rotation of the cut, ensuring uniformity across the items. This is almost perfect, although the odd one does miss the mark on occasion.

All of these features add together to make a powerful case for purchase. The F1 Ultra is fast, accurate and adaptable to different uses. You could be an individual looking for a capable desktop laser engraver or you could be a crafter with an Etsy store, looking to sell personalised items alongside your own custom items. No matter what this laser will do the job. Yes, it’s expensive but it is very well made and caters to the needs of the individual or small business very well.

Software and user experience

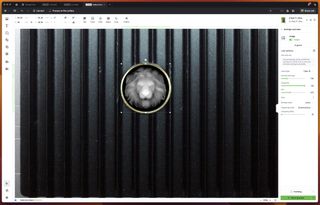

XTool’s software for the F1 Ultra is called XCS. It’s a fairly intuitive application, with options for designing using standard operations and shapes, an area for doing layout, setting laser parameters and so on.

A click of the camera icon displays an image of the current state of the machine, which makes it easy to line up a design with your chosen material. Combined with the framing tool, this works really well.

You can also jump to the design find community/store where you’ll find a bunch of projects in all sorts of styles, pre-made with settings for materials, which can be imported directly to XCS.

For those who want something custom but aren’t confident designers, there’s even an AI tool, allowing you to type in a prompt and have the software create something bespoke. I tested this out and it works fine but I’d much rather use my own designs. Nice to have though.

I do like that there’s a materials button top right, that opens up a library where each material can be chosen, with suitable settings for the F1. After testing a bunch of these I can say they produce pretty good results but this will be dependant on where you source your materials. I tried black metal business cards from a number of stores and they aren’t made equally. They all worked but some tweaking to get the best results was needed on some.

Price

The F1 Ultra ranges from £4,579 – £6,112, although XTool regularly runs sales with significant discounts.

Although not exactly cheap, you can choose the bundle which suits your needs the best, so you won’t be paying for anything you don’t need. The overall value is pretty reasonable though, as the mix of build quality, performance and capabilities is really very good.

Who is it for?

The F1 Ultra is for anybody looking for a laser engraver/cutter that can handle multiple material types, cuts fast and has the option for batch processing. Embossing is a pretty new option but adds an exciting opportunity for the creative.

Buy it if…

- You work across varied materials

- Accuracy is important

- You’d like to produce bulk orders

- You have limited space

Don’t buy it if…

- You’re on a limited budget

- You need to cut larger sheet material